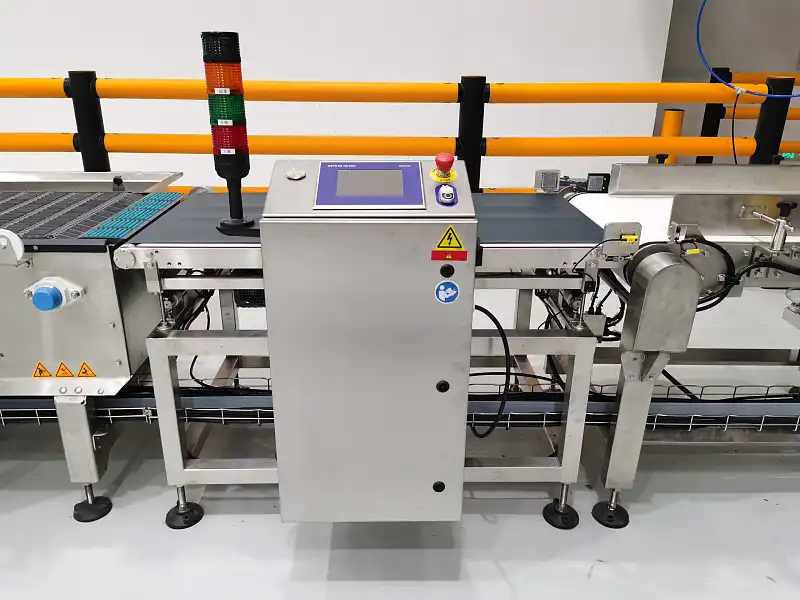

Assessment and Improvement of Safety Performance of Non-Standard Conveyors

In industrial production, non-standard conveyors serve as crucial equipment for material handling. Their safety performance directly affects production efficiency and personnel safety. Therefore, it is particularly important to regularly assess and enhance the safety performance of non-standard conveyors. This article will provide a detailed introduction to the assessment methods of the safety performance of non-standard …

Continue reading “Assessment and Improvement of Safety Performance of Non-Standard Conveyors”