Conveyor belts are essential equipment in industrial production, bearing the responsibility of material transportation and directly impacting production efficiency and operational costs. When designing and selecting conveyor belts, durability and service life prediction are crucial considerations. This article will delve into the durability of conveyor belts and the design of service life prediction, providing valuable insights for engineers and decision-makers.

I. What Does Conveyor Belt Durability Mean?

Conveyor belt durability refers to its ability to operate continuously and stably under predetermined working conditions without frequent maintenance or replacement of key components. Durability is influenced by various factors, including:

1. Material Selection: The choice of materials for constructing the conveyor belt must possess adequate strength and resistance to wear to withstand the impact and abrasion from materials being transported.

2. Design Parameters: Conveyor belt design parameters such as belt speed, load-carrying capacity, and conveying distance must match specific application requirements.

3. Maintenance Management: Regular maintenance and inspections are vital for extending the conveyor belt’s service life.

4. Environmental Conditions: The environmental conditions in which the conveyor belt operates, including temperature, humidity, and the presence of chemicals, can directly affect its durability.

II. How to Predict the Service Life of Conveyor Belts?

To ensure the long-term reliability of conveyor belts, service life prediction is indispensable. The following are methods for predicting the service life of conveyor belts:

1. Stress Analysis: Analyzing the stress and strain on various critical components of the conveyor belt can predict their service life. This often requires engineering tools such as finite element analysis.

2. Material Research: Research into the materials used in conveyor belts can determine their fatigue characteristics and durability, aiding in service life prediction.

3. Maintenance Records: Regularly documenting maintenance and repair of the conveyor belt provides historical data that can be used to predict future service life.

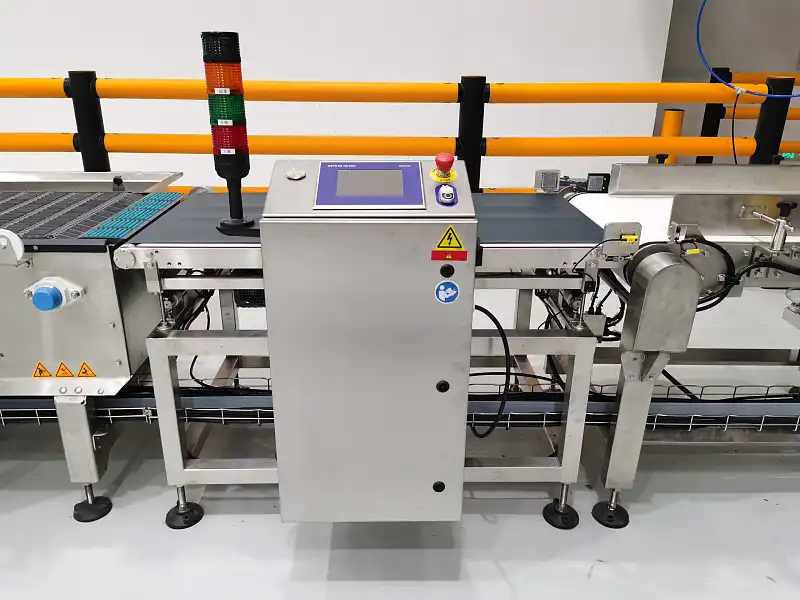

4. Monitoring Systems: Installing monitoring systems to track the conveyor belt’s operational status and health in real-time helps identify issues promptly and take corrective measures.

III. How to Design Conveyor Belts for Improved Service Life?

During the design phase of conveyor belts, several measures can be taken to enhance their service life:

1. Appropriate Material Selection: Choosing materials with high strength and good wear resistance extends the conveyor belt’s service life.

2. Well-Structured Design: Designing a well-balanced structure ensures that all components experience even loading, reducing fatigue and stress concentration.

3. Adequate Maintenance Space: Designing with maintenance and inspection spaces in mind allows for regular maintenance and servicing.

4. Safety Considerations: Ensuring the conveyor belt design complies with relevant safety standards reduces the risk of accidents and lowers maintenance costs.

5. Integration of Monitoring Systems: Integrating monitoring systems during design allows for real-time tracking of the conveyor belt’s status, facilitating timely issue detection and resolution.

IV. Case Study: Successful Practices in Improving Conveyor Belt Service Life

Here is a successful case demonstrating how proper design and maintenance can enhance the service life of conveyor belts:

Case Study: A mining company experienced frequent breakdowns in their conveyor belt system, resulting in production downtime and high maintenance costs. After a comprehensive analysis, the company implemented the following measures:

1. Redesigned the conveyor belt structure to enhance the strength and wear resistance of critical components.

2. Conducted regular maintenance and replaced severely worn components to ensure the conveyor belt remained in optimal condition.

3. Installed a real-time monitoring system to track the operational status of the conveyor belt and detect issues promptly.

Results: Through these measures, the company successfully extended the service life of the conveyor belt, reduced the failure rate, lowered maintenance costs, and improved production efficiency.

Durability and service life prediction design for conveyor belts are critical considerations in industrial production. By selecting appropriate materials, optimizing design structures, implementing regular maintenance, and integrating monitoring systems, the service life of conveyor belts can be effectively extended, reducing operational costs and enhancing production efficiency. Engineers and decision-makers should gain a deep understanding of these principles and apply them to the design and operation of conveyor belts to ensure the long-term reliability of their equipment.