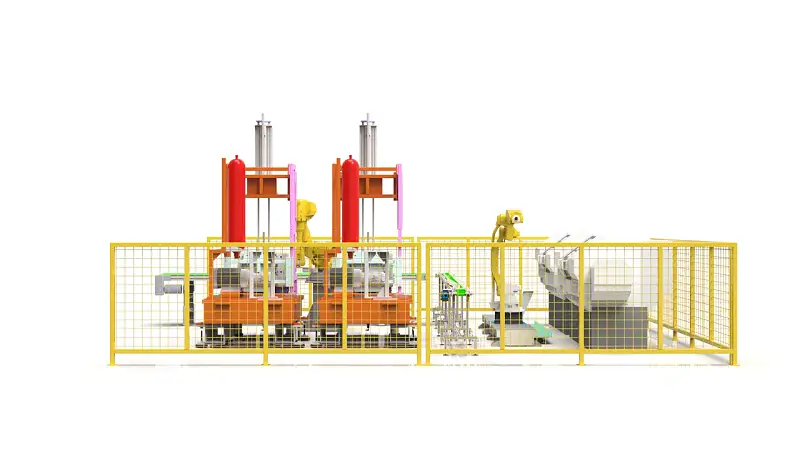

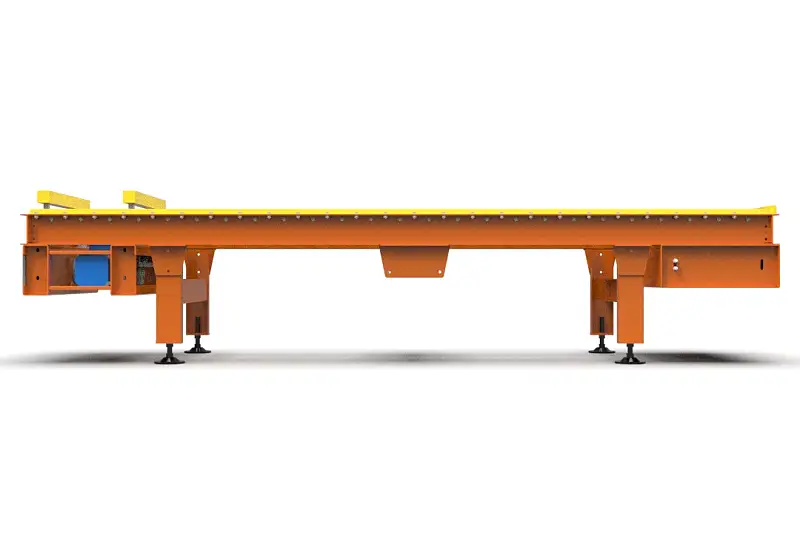

The detachable and modular design of conveyors: key technologies to improve equipment performance and convenience

Conveyor as an important logistics transportation equipment, is widely used in mines, ports, chemicals, food, pharmaceutical and other industries. To meet various production needs, conveyors are constantly evolving in design, among which detachable and modular design have become a key part. Detachable Design of Conveyor Detachable design allows conveyors to be easily disassembled and installed …