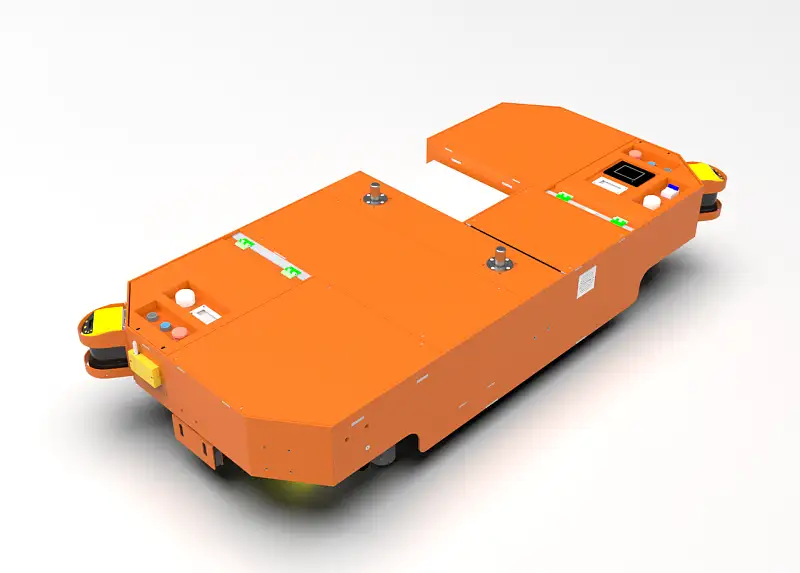

AGV (Automated Guided Vehicle) integration with intelligent warehouse systems has become an essential means to improve storage efficiency and management levels. This article will focus on discussing practical experiences and optimization strategies for AGV integration with intelligent warehouse systems, providing readers with insights and applications in this specialized field.

I. Sharing Practical Experiences

1. Comprehensive Planning and Layout of AGV and Intelligent Warehouse Systems

Before implementing AGV integration with intelligent warehouse systems, enterprises need to conduct a series of planning and layout work. Firstly, determine the quantity and types of AGVs based on specific warehouse conditions and requirements. Secondly, ensure that the warehouse’s layout and road design meet the driving requirements of AGVs, avoiding issues such as narrow spaces or excessive corners that may impact efficiency. Additionally, consider smooth integration between AGVs and intelligent warehouse systems, ensuring real-time data transmission and processing.

2. Optimization and Scheduling of AGV Tasks

To maximize storage efficiency, optimizing and scheduling AGV tasks is crucial. Firstly, based on warehouse layout and operational requirements, establish a rational task allocation strategy enabling AGVs to efficiently complete pick-up and delivery tasks. Secondly, employ intelligent scheduling systems that dynamically allocate tasks to AGVs based on real-time data and optimization algorithms, thus avoiding conflicts and redundancies and improving resource utilization and response speed.

3. Data Sharing and Collaborative Optimization

Data sharing and collaborative optimization are critical in AGV integration with intelligent warehouse systems. Seamless data connectivity and sharing allow for collaborative work among warehouse systems, AGV control systems, and enterprise management systems. This boosts storage efficiency and management levels. Furthermore, data analysis and mining can support operational decision-making, optimizing warehouse processes and resource allocation.

1. Iterative Optimization and Continuous Improvement

Optimization is an ongoing process in AGV integration with intelligent warehouse systems. Enterprises should establish a comprehensive operational performance measurement system, conducting regular assessments and analyses to identify issues and drive improvements. Additionally, keeping abreast of technological advancements and innovations is key. Timely adoption of new technologies and tools continually enhances the performance and efficiency of integrated systems.

2. Intelligent Management and Human-Machine Collaboration

With the rapid development of artificial intelligence and machine learning technologies, intelligent management holds great potential in AGV integration with intelligent warehouse systems. Enterprises can integrate monitoring, alert systems, and decision-making capabilities, enabling end-to-end intelligent management of warehouse operations. Simultaneously, emphasis should be placed on human-machine collaboration, combining human expertise with intelligent systems to achieve more efficient warehouse management.

3. Safety Risk Control and Emergency Preparedness

Efficiency and management are not the sole considerations for AGV integration with intelligent warehouse systems. Attention must also be given to safety risk control. Enterprises should conduct assessments of system security before implementation, developing corresponding safety measures and emergency response plans. For instance, installing sensors and cameras to monitor AGV movements in real-time facilitates timely detection and appropriate action in response to abnormal situations. In addition, training and drills should be conducted to enhance employee awareness and capabilities in handling safety risks effectively during emergencies.

4. Knowledge Sharing and Industry Collaboration

Promoting knowledge sharing and industry collaboration is essential during AGV integration with intelligent warehouse systems. Participating in industry conferences, exchanging experiences, and establishing collaborative platforms allow enterprises to discuss problems, share best practices, and innovative experiences with other companies, experts, and research institutions. This not only acquires valuable industry information and technical support but also expands horizons for development, providing more opportunities for self-growth.

The practical implementation and optimization of AGV integration with intelligent warehouse systems present both challenges and enormous potential. By sharing practical experiences in planning and layout, task optimization and scheduling, and data sharing and collaborative optimization, storage efficiency and management levels can be enhanced. Furthermore, through iterative optimization and continuous improvement, intelligent management and human-machine collaboration, safety risk control and emergency preparedness, and knowledge sharing and industry collaboration, the performance and safety of integrated systems can be continuously improved. AGV integration with intelligent warehouse systems will play a significant role in achieving more efficient, intelligent, and sustainable development within the logistics industry, providing strong support for enterprises’ competitiveness and innovation capabilities.