Research on Adaptive Scheduling Strategies of AGVs in Flexible Manufacturing Systems

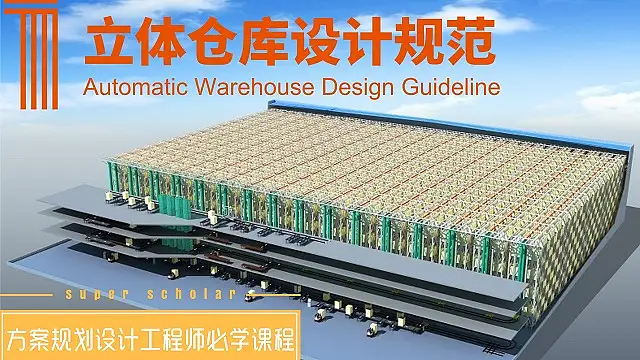

In recent years, with the rapid development of the manufacturing industry, Flexible Manufacturing Systems (FMS) have become a crucial tool for improving production efficiency and reducing costs. In the context of FMS, Automatic Guided Vehicles (AGVs) play an increasingly prominent role as key logistics nodes, making the study of adaptive scheduling strategies essential for enhancing …