As an efficient and reliable material handling equipment, conveyors play an indispensable role. This article will explore the future development trends and innovative design of conveyors, presenting readers with exciting prospects in this field.

1、 Innovation in automation technology driving conveyors:

Automation technology is one of the key factors driving the development of conveyors. With the rapid development of artificial intelligence, machine learning, and sensor technology, conveyors are moving towards intelligence and automation. Whether in the fields of material sorting, classification, or warehouse handling, the application of automation technology provides higher operating efficiency and accuracy for conveyors. For example, conveyors based on computer vision and machine learning algorithms can achieve automatic identification and sorting of items, greatly improving the speed and accuracy of logistics operations.

2、 Key to Sustainable Development: Green Conveyor Design and Energy Optimization:

With the increasing awareness of environmental protection and sustainable development, green conveyor design has become a hot topic in the industry. Traditional conveyors may cause energy waste and environmental pollution during operation. Therefore, by optimizing design and adopting energy-saving technologies, energy recovery and reuse during the transportation process can be achieved. For example, some advanced conveyor designs convert inertial energy during transportation into electrical energy and store it in batteries for subsequent use by installing energy recovery devices. In addition, the use of lightweight materials and precise control systems can also reduce the energy consumption of the conveyor and reduce its impact on the environment.

3、 Flexible and variable transportation systems:

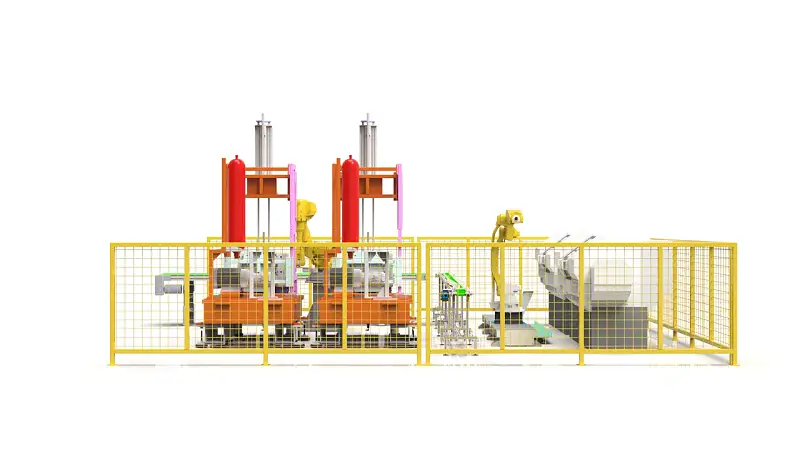

To adapt to rapidly changing logistics needs, conveyors need to have the characteristics of flexibility and variability. Traditional conveyors are usually fixed and cannot adapt to changes in different materials and work scenarios. Therefore, the design of flexible conveyors has become a new research direction. Flexible conveyors can automatically adjust the conveying speed, angle, and path based on changes in material type, size, and transportation distance to meet different logistics needs. In addition, some innovative designs combine robotic arms and conveyors to achieve automatic material grabbing and placement, further improving conveying efficiency and flexibility.

4、 Data analysis and intelligent optimization:

With the informatization development of the logistics industry, big data analysis and intelligent optimization have become the key to the future development of conveyors. By collecting and analyzing data generated during the transportation process, real-time monitoring and optimization of the transportation link can be achieved. For example, obtaining the working status data of the conveyor through equipment sensors and using data analysis technology for fault prediction and maintenance plan optimization can avoid downtime and production losses caused by equipment failures. In addition, data analysis can also identify and optimize bottlenecks and defects in the transportation process, improving transportation efficiency and quality. The application of intelligent optimization algorithms can help conveyors achieve optimal path planning and resource scheduling, reducing transportation time and costs.

5、 The development trend of human-machine collaboration:

Despite the increasingly widespread application of automation technology in the field of conveyors, human-machine collaboration is still indispensable. Future conveyor design should focus on the flexibility and safety of human-machine cooperation. For example, by introducing wearable devices and robot navigation systems, operators can interact with conveyors in real-time, achieving more efficient and safe logistics operations. In addition, the improvement of education, training, and personnel management systems is also an important part of ensuring human-machine collaboration.

With the rapid development of the logistics industry and the continuous pursuit of efficiency, conveyors, as the core equipment for material handling, are facing opportunities for innovation and development. Innovations in automation technology, green design, flexible systems, data analysis, and human-machine collaboration will drive the conveyor industry into a new stage of development.