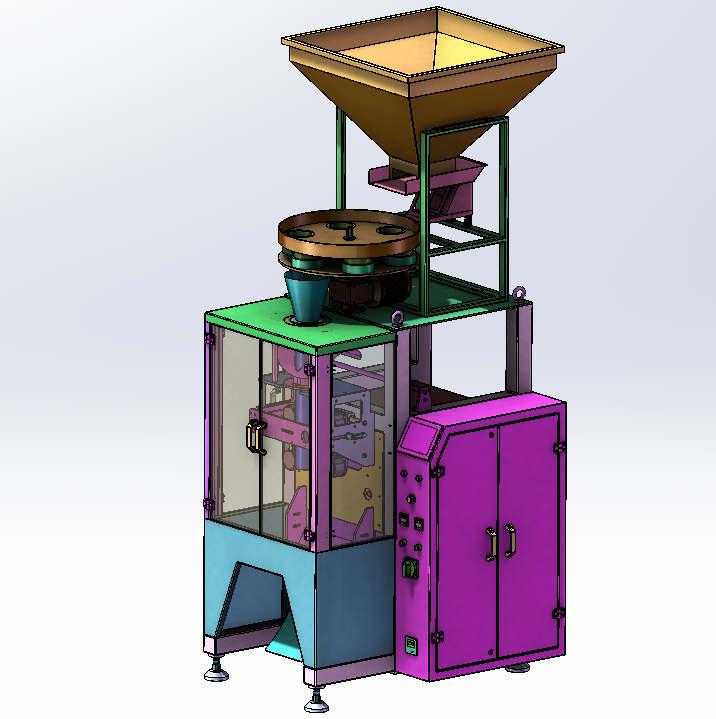

This machine is widely used to pack granular materials, such as sugar, coffee, salt, MSG, flavouring, sunflower seeds, puffed food, nuts, tea, herbs, peanuts, beans, rice, grains, washing powder, etc.

Working Principle:

1.Workflow: cup volumetric filler measuring→coding(optional)→bag making→filling→gas injection/exhaust(optional)→sealing→couting.

2.Computer control, photoelectric tracking, has fault display system, easy to operate and maintain.

3.Can make hole punching blade(round/euro hole), linked bags device or easy tear notch device and so on according to customer’s request.

4.Machine body and all product touching parts are made of stainless steel.

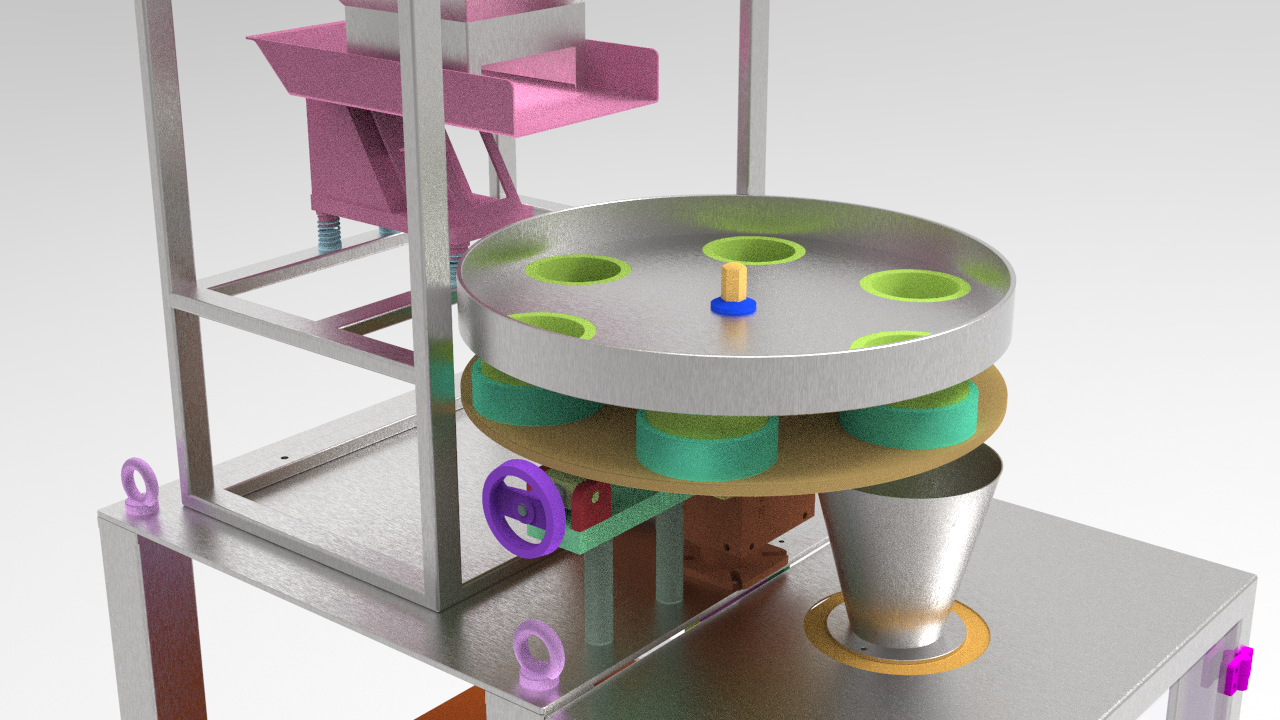

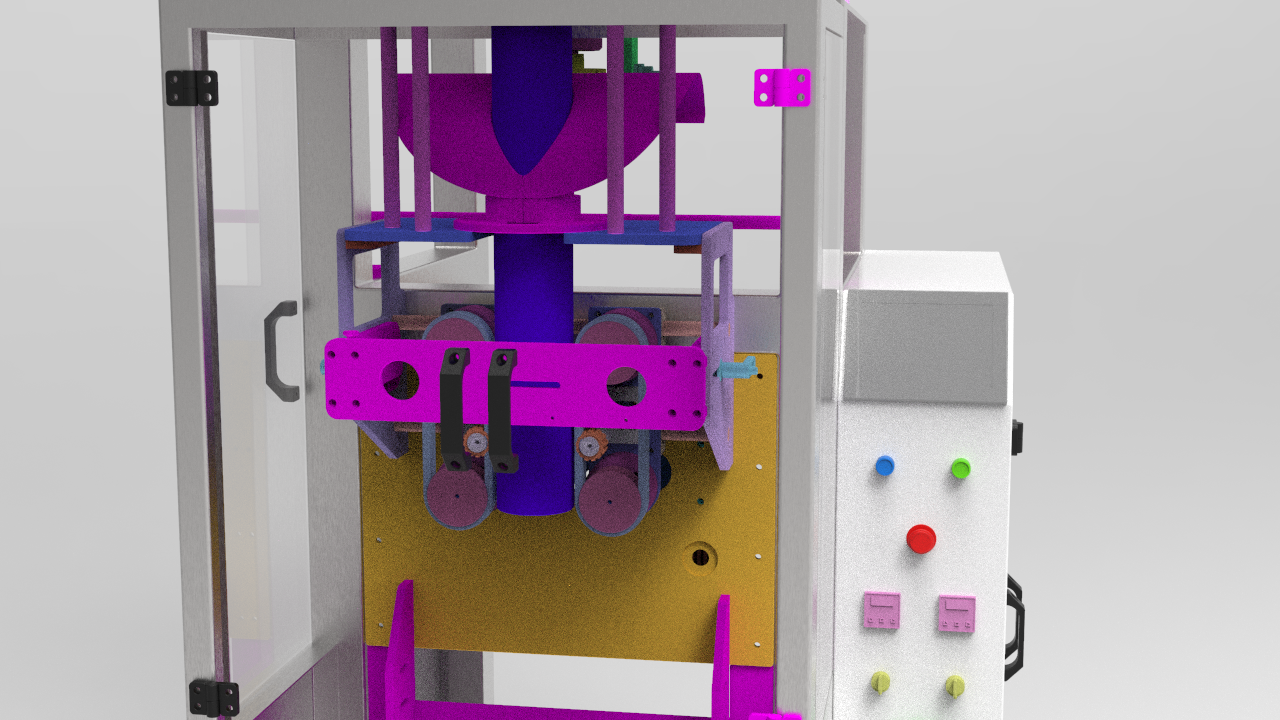

This 3D model designed by SolidWorks 2017, detailed design including every part like pictures below, step files included for you. The file total of 32 MB.

| Packing speed | 30-80 bags/min |

| Packing range | 5-200ml |

| Film width | ≤ 280mm |

| Making bag size | L: 50-150mm, W: 30-140mm |

| Packing accuracy | ≤ ±1% |

| Power | 1.6 kW |

| Power supply | AC220V, 50/60Hz |

| Seal type | Pillow sealing 3/4 sides seaing |

| Net weight | 250kg |

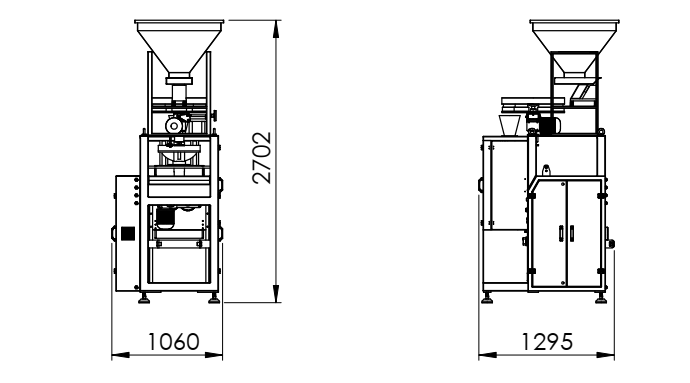

| Machine dimension | L1200 × W110 × H2700mm |