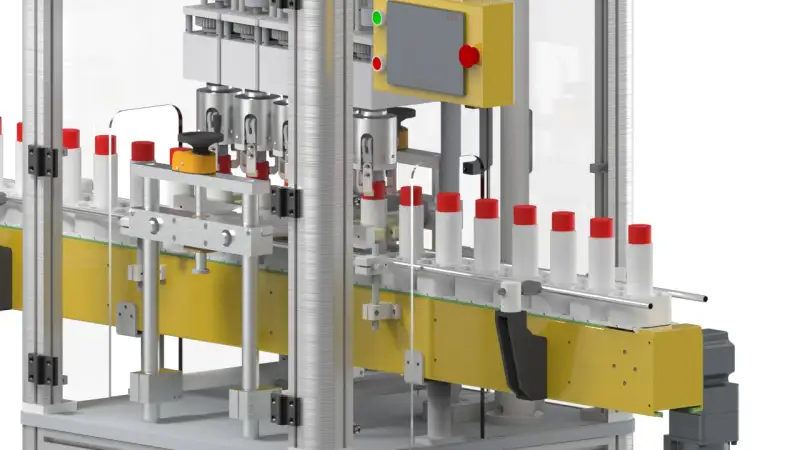

A fully automatic capping machine is an automated equipment. It mainly consists of mechanical structure, electrical control system, and transmission device. During work, the bottles to be capped will be fed into the working area of the capping machine through a conveyor belt.

Firstly, the mechanical structure will position the bottle to be capped in the correct position, ensuring that the lid is correctly aligned with the bottle mouth. Subsequently, the electrical control system will activate the capping machine to start working.

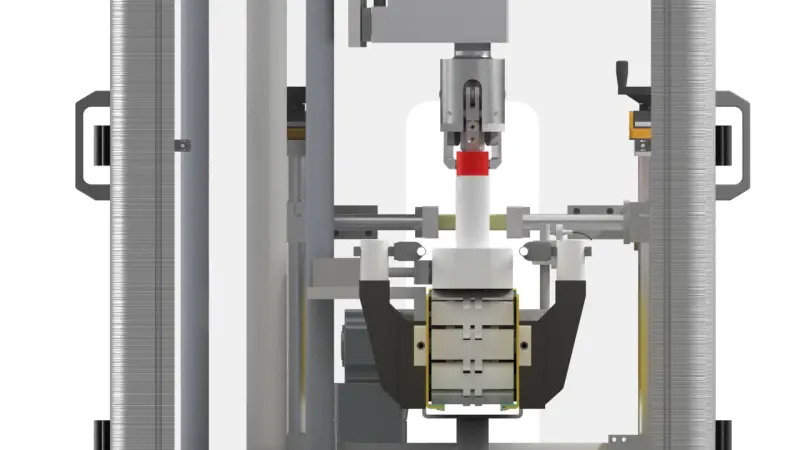

The transmission device will start the motor and transmit power to the capping machine head through the transmission device. The rotary capping machine is equipped with a rotating bottle capper inside, which will remove the cap from the cap storage device and accurately transport it to the mouth position of the bottle to be capped.

The cap is correctly aligned with the bottle mouth, and the mechanical structure will clamp the cap and rotate it onto the bottle mouth through the rotation of the capping machine head. At the same time, the capping machine head will control the force according to the preset torque to ensure that the lid is properly tightened.

After tightening the lid, the capping machine will transfer the bottle to the next work area or move it to the next device through the conveyor belt. At the same time, the capping machine prepares the bottle to be capped and waits for the next operation.

Through this principle, the fully automatic capping machine can efficiently cap a large number of bottles. Its automation features improve production efficiency and reduce manpower requirements.

This 3D model was designed by SolidWorks 2017, the file totaling is 77 MB, including step files for other 3D software open.