The checkweighing and sorting system is an online weight sorting device and an automatic checkweigher manufactured based on the dynamic resolution provided by high-precision weighing sensors. It can classify products that do not meet the qualified weight range in accordance with regulatory requirements, and can also Products can be graded according to weight class requirements. Fast and precise sorting thanks to integrated weighing technology.

The weighing and sorting system is used to dynamically weigh and classify products in automated packaging lines, such as box weight sorting systems, food and fruit and vegetable sorting systems, seafood sorting systems, logistics sorting systems, pharmaceutical sorting systems, etc. .

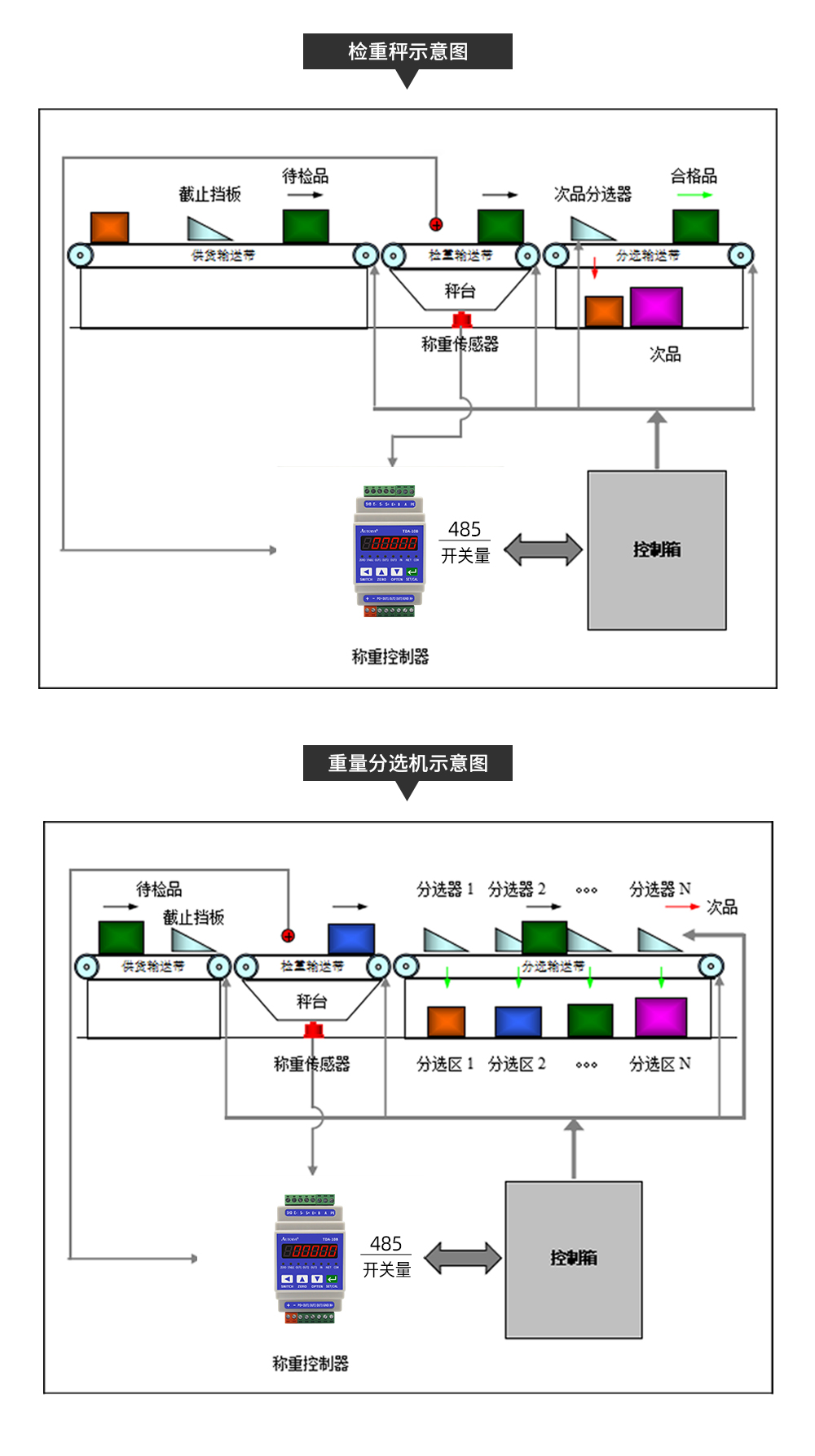

Working principle and sorting form of automatic batching and weighing system

Working principle:

The checkweighing and sorting system uses dynamic weighing technology to detect the weight of products. Different detection accuracy can be obtained by using different weighing sensors.

Weighing and sorting machine, the weighing system is the core part of the weighing and sorting machine, which determines the detection accuracy and operation stability of the weighing and sorting machine. weighing

The measuring range of the sensor determines the weighing size of the weighing and sorting machine.

Sorting type:

①Reject unqualified products.

②Reject or transport overweight and underweight products to different places respectively.

③Divided into different weight categories according to different weight ranges.

④ Product missing inspection.