Current status of the industry: The more manual material loading is used in the entire production process of an enterprise, the more links there will be errors. The superposition of each other will greatly affect the stability and yield of the product. At present, cement ingredients, steel, chemicals, food, new energy and other industries are pursuing production efficiency, product quality control, including yield rate, and automation transformation is imminent. Some companies have relatively large dust and other pollution, and employees working on production lines for a long time will have a certain impact on their health. In addition, society’s requirements for environmental protection are getting higher and higher, and the original equipment needs to be upgraded.

Purpose of transformation: Improve production efficiency: The loss-in-weight scale can continuously and dynamically weigh materials during the production process, control the amount of cutting per unit time, and improve the uniformity of cutting.

Improve weighing accuracy: The loss-in-weight scale uses high-precision sensors and advanced control algorithms to monitor the weight of the materials being discharged in real time and control it, thereby improving the weighing accuracy and reducing errors: Since the loss-in-weight scale uses a dynamic The weighing method can monitor the weight of materials in real time during the production process, thus reducing errors caused by factors such as excessive residence time of materials.

Improve product quality: The weighing and control of loss-in-weight scales can ensure the weight consistency of materials during the production process, thereby improving product quality.

Reduce labor intensity: The loss-in-weight scale has a high degree of automation, which can reduce manual operations and intervention, thus reducing labor intensity. In general, loss-in-weight scales can solve the pain points of dynamic weighing of materials during the production process, improve production efficiency, weighing accuracy, product quality, and reduce labor intensity.

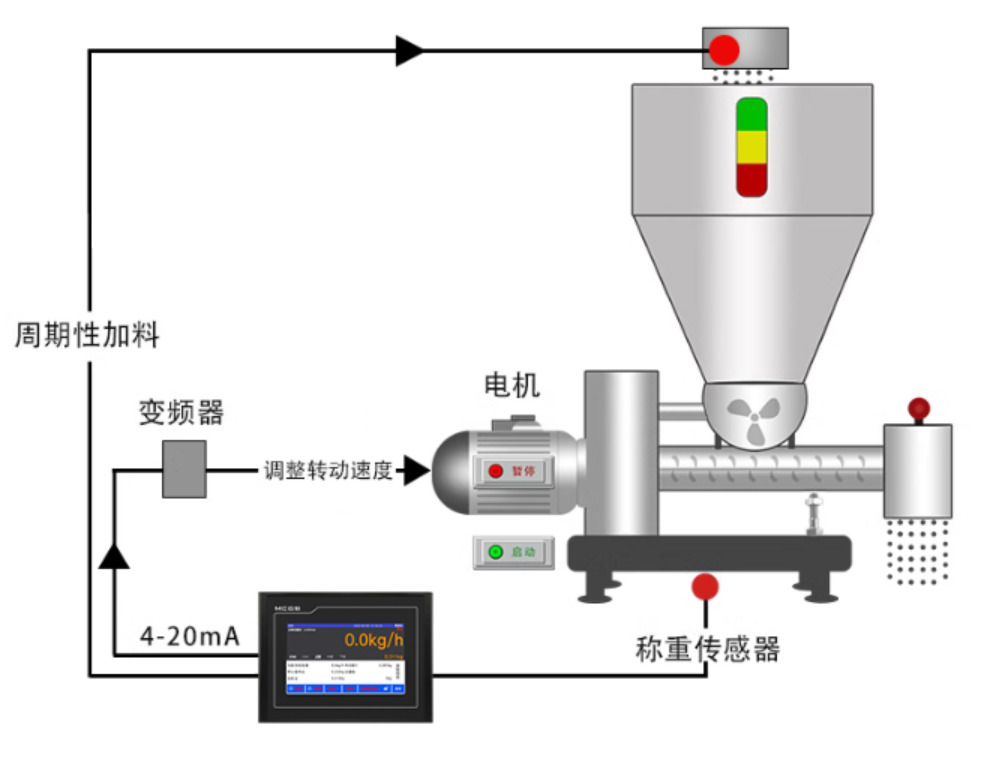

Loss in weight scale solution

Designed and experimented by the Oluda Intelligent Technology R&D team, using the company’s high-precision weighing sensors, Ethernet data processors and other hardware products, combined with software calculation programs, and with the support of the Internet of Things, artificial intelligence and other technologies, Weightless scales will be able to better achieve intelligence, automation, remote control, etc.