With the rapid development of the logistics industry, modern warehouses have become an indispensable part. The shuttle car system, as an advanced logistics technology, plays a crucial role in solving many problems in the warehouse with its unique characteristics and advantages. This article will delve into the role of shuttle car systems in modern warehouses, helping you better understand the advantages of this efficient handling tool.

I、Introduction

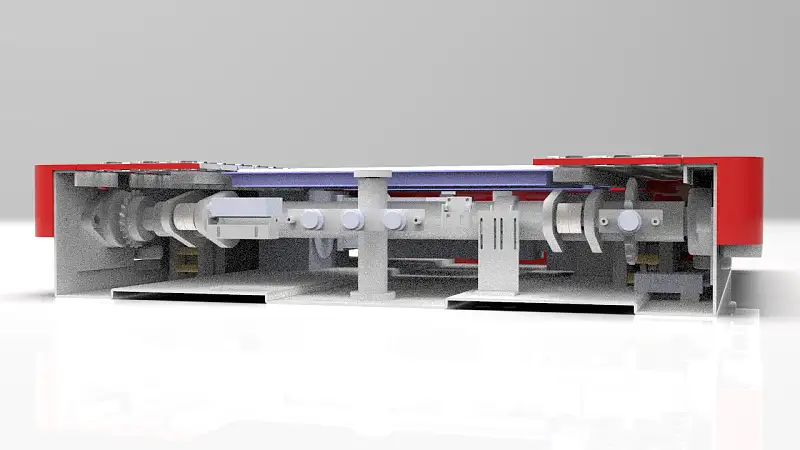

The shuttle car system is an automated, intelligent goods handling system. It mainly consists of tracks, shuttle cars, shelves, and control systems. The track is the main road of the system throughout the warehouse; shuttle cars travel on the track and are responsible for the handling of goods; shelves are used for storing goods; and the control system is the central nervous system of the entire system, controlling the operation of the entire system.

II、The Role of Shuttle Car Systems in Modern Warehouses

1. Improving overall warehouse efficiency

The shuttle car system uses automation technology to significantly improve the speed of goods handling in the warehouse. Compared to traditional manual handling, the shuttle car system can reduce labor costs and improve handling efficiency. At the same time, due to the fast response ability of the shuttle car system, it can quickly sort and distribute goods according to order requirements, shortening the time of goods storage in the warehouse, and thereby improving the overall operational efficiency of the warehouse.

2. Reducing labor costs

The shuttle car system can completely replace manual handling, reducing employee workload and labor costs. At the same time, due to the automated and intelligent characteristics of the shuttle car system, it can reduce human errors and improve the accuracy of goods handling. In addition, the shuttle car system can also work continuously 24 hours a day, improving work efficiency.

3. Reducing cargo damage rate

The shuttle car system uses a track and pallet method for goods handling, and the goods will not be subjected to violent vibrations or collisions during transportation, thereby reducing the possibility of cargo damage. At the same time, due to the advanced sensors and anti-collision devices used in the system, it can effectively avoid cargo damage caused by manual operation errors.

4. Improving cargo accuracy

The shuttle car system combines barcode, RFID, and other technologies to achieve automatic identification, which can reduce human errors and improve the accuracy of goods identification. In the sorting process, the system can automatically match information based on order requirements to ensure accurate delivery of goods. In addition, the system can also track and monitor goods in real time, providing timely feedback on abnormal situations and improving the transparency of cargo management.

5. Flexibly responding to business changes

As markets constantly change and business volumes grow, warehouses often need to be continuously adjusted and expanded. The shuttle car system can be flexibly adjusted according to business requirements. For example, adjusting track layouts or increasing or decreasing shuttle car numbers based on different storage requirements can be easily achieved with shuttle car systems. In addition, due to its scalability, shuttle car systems can easily cope with future business growth requirements.

III、Conclusion

As an important component of modern warehouses, shuttle car systems bring enormous advantages to warehouse operations with their efficient, accurate, and flexible characteristics. By improving overall warehouse efficiency, reducing labor costs, reducing cargo damage rates, improving cargo accuracy and flexibly responding to business changes, shuttle car systems provide strong support for modern warehouses. With ongoing technological advancements and the continued development of the logistics industry, it is reasonable to believe that shuttle car systems will play an increasingly important role in the future.