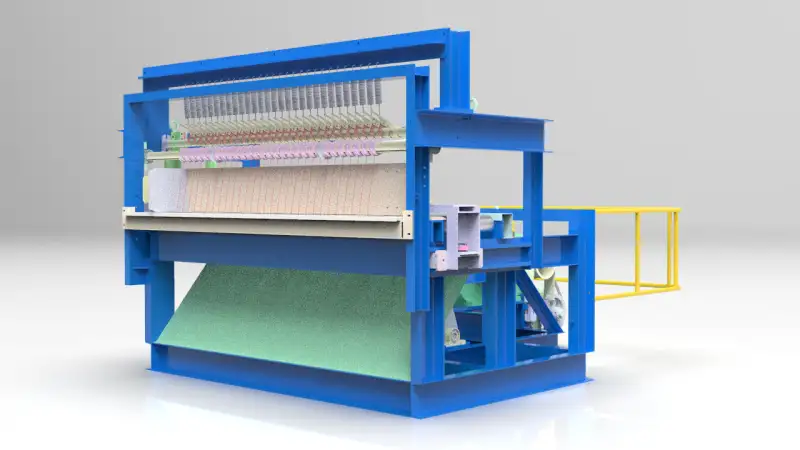

3D design of brick cutting machine equipment

Cutting machine belongs to building materials machinery, which is widely used in brick factories and kilns. It is mainly used for cutting solid brick or perforated brick, and also for cutting thin-walled large holes. It is the last processing equipment in the brick forming process.

The cutting machine is the processing equipment of the last process in the brick forming process. It cuts the mud bar with certain geometry shape extruded by the screw extruder into the green body with the same thickness and in line with certain specifications. There are many types of cutting machine, such as push rod cutting machine, chain cutting machine, single number automatic cutting machine and multi wire cutting machine, among which push rod cutting machine is widely used. The cutting machine is composed of cutting table, sample plate, push rod and copper sleeve. The push rod type cutting machine has the characteristics of compact structure, simple operation, easy maintenance and high output. The vast majority of brick and tile factories in China use this type of cutting machine.

Cutting machine for non load bearing hollow products

Its characteristic is that the whole process of the mud bar input into the cutting machine and output by the cutting machine after it is cut into bricks is carried out by using the roller table, so the surface quality of the mud bar can be guaranteed. In order not to affect the shape and size of the brick during cutting, the mud bar is still when cutting, and the cutting is completed by the movement of the steel wire.

The mud bar quickly sent from the mud bar cutting machine is driven by a series of idlers driven by a braking deceleration motor and moves to the worktable of the cutting machine. Before reaching the terminal position, the mudsliver causes the first photoelectric tube to send out a signal, and the motor cuts off power to slide, so that the mudsliver also decelerates; when the mudsliver reaches the correct terminal position, the second photoelectric tube sends out a signal, and the motor brakes, so that the mudsliver stops at the correct position of the worktable of the cutting machine.

The design based on SolidWorks 2017, please use 2017 or above to open. The file is about 20.5 MB.