Introduction:

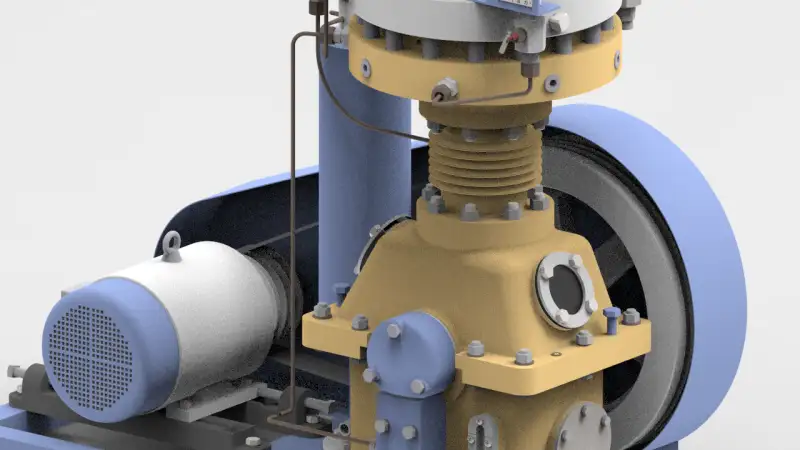

Diaphragm compressor is one of the many types of compressors. Because of its special diaphragm, the compressed medium is separated from the outside world. Diaphragm compressor can also be referred to as membrane compressor. Diaphragm compressor because of its special structure, the cylinder does not need lubrication, sealing performance is very good, the compression medium does not contact with any lubricant, so it can compress high purity gas, generally can reach 99.999% purity, is more suitable for compressing and transporting all kinds of precious rare gas. In addition, for corrosive, radioactive, toxic and explosive gases, diaphragm compressor is especially suitable. The air cylinder of diaphragm compressor has good heat dissipation and high compression ratio, so its pressure range is wide, and the maximum discharge pressure can reach 500MPa. It is used in food industry, petroleum industry, chemical industry, electronic industry, nuclear power plant, aerospace, military equipment, medicine, scientific research and other fields.

Working principle:

Diaphragm machine belongs to the displacement compressor, which can compress the gas by changing the volume of the air cavity by the deformation of the diaphragm.

- Compressed medium: gas

- Lubrication mode: oil free

- Intake pressure: 5 Mpa

- Exhaust pressure: 35 Mpa

- Overall dimensions: 1300*700*1200

- Application: civil, military, industrial, aviation

- Power: 2.2 kw

- Transmission mode: belt drive

This design model drawn by SolidWorks 2018, the model is detailed design. The original 3D file allows you to quickly modify the design. The step format file is provided for opened by other 3D software. The package size is approximately 154 MB.