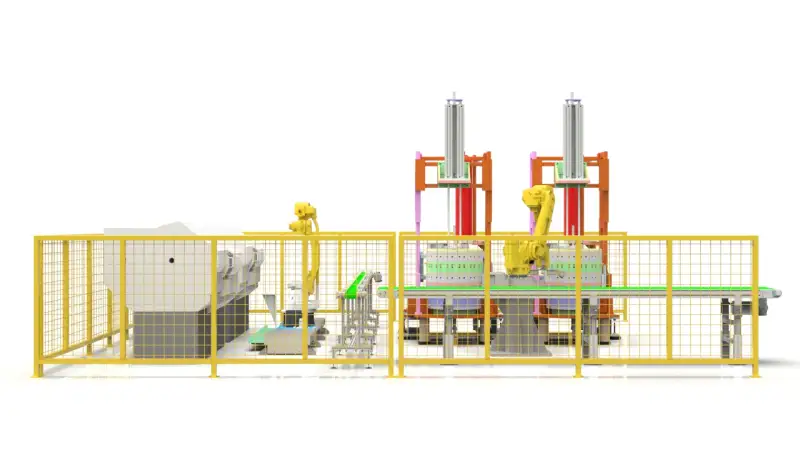

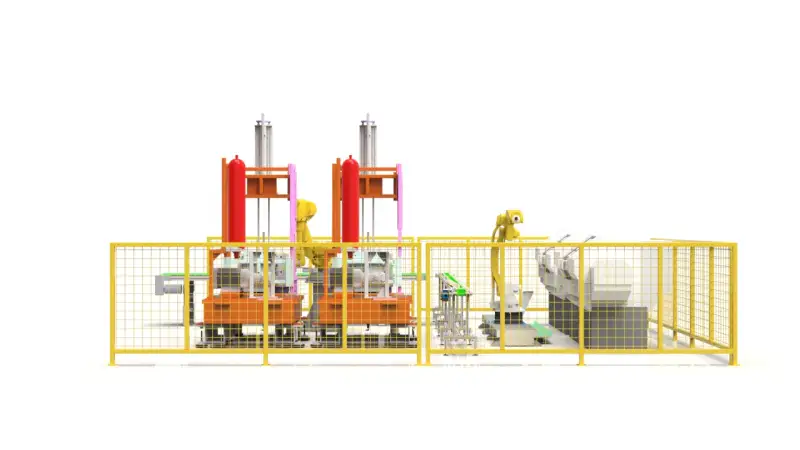

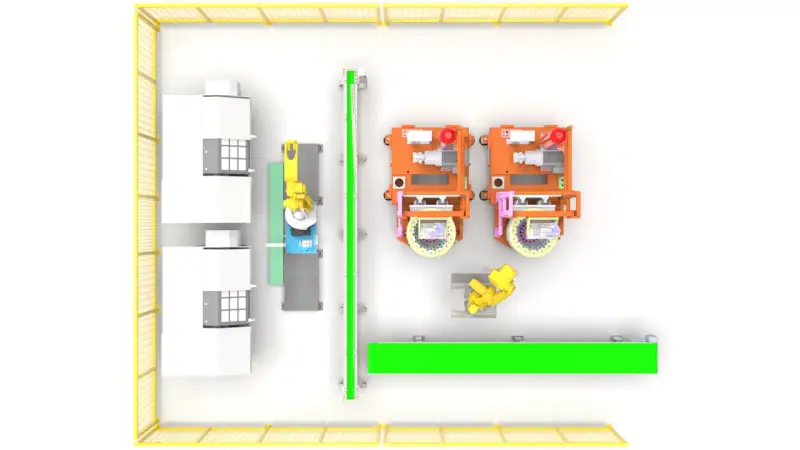

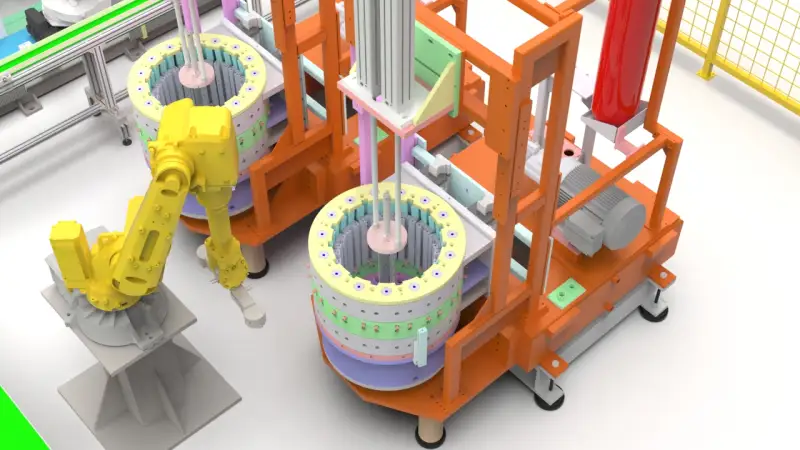

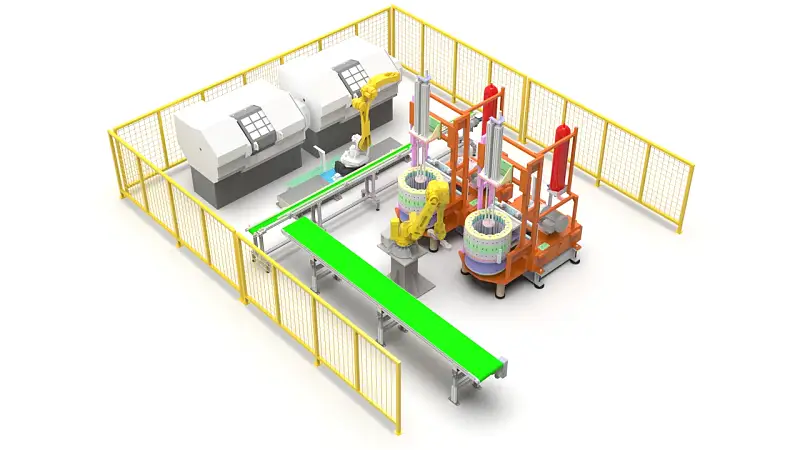

This project involves the creation of a comprehensive 3D model design for an electric motor shaft assembly line. The 3D model encompasses the entire manufacturing process, from raw material input to the final assembly of the motor shafts.

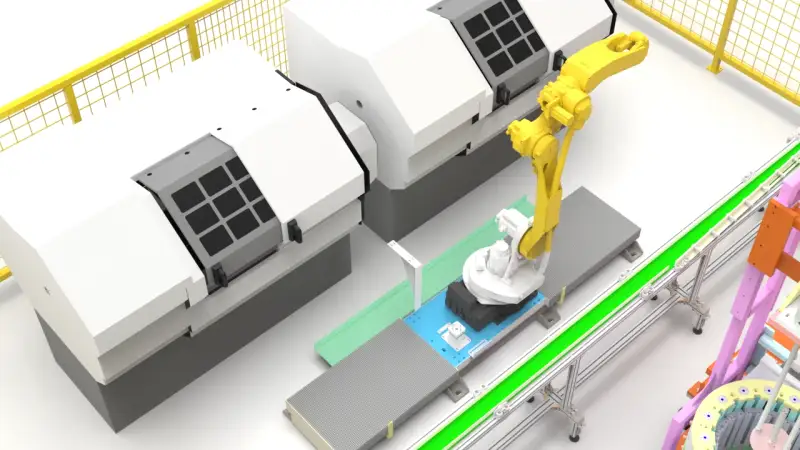

The design incorporates cutting-edge technology and optimization techniques to ensure the efficient and smooth operation of the assembly line. It includes detailed representations of the various components and machinery involved, such as conveyors, robotic arms, machining tools, inspection stations, and quality control systems.

By visualizing the entire assembly line in a 3D model, manufacturers can gain a clear understanding of the layout, spatial relationships, and potential optimization opportunities. This allows for better planning, improved productivity, and the ability to identify and resolve any potential bottlenecks or issues in advance.

The 3D model can also serve as a valuable tool for training purposes, enabling operators to acquire a comprehensive understanding of the assembly line and its processes before actual implementation.

The 3D modeling design of this electric motor shaft assembly line offers a practical and efficient solution for manufacturers aiming to enhance productivity, quality control, and operational efficiency in the production of motor shafts.

This 3D design was created using SolidWorks 2017. The file size is 187 MB, which includes a step file that can be opened in other 3D software.