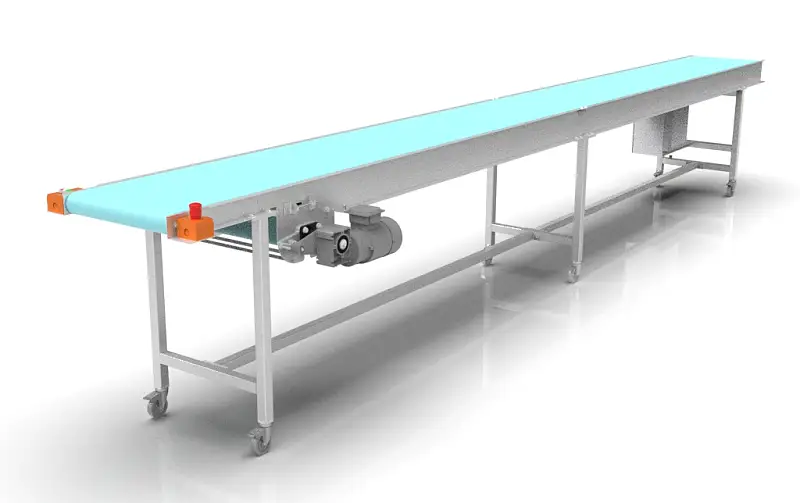

The food industry relies heavily on the modular belt conveyor as a crucial part of its manufacturing process. Its primary purpose is to transfer food products securely from one location to another, which is why it must have a hygienic design that adheres to food safety standards. The Solidworks 3D design model of this conveyor demonstrates its durability, seamless operation, and effectiveness in transporting food products along the production line.

Design:

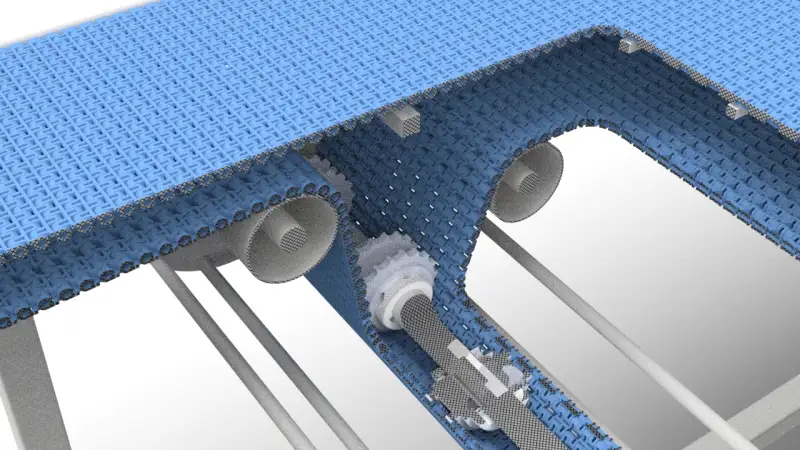

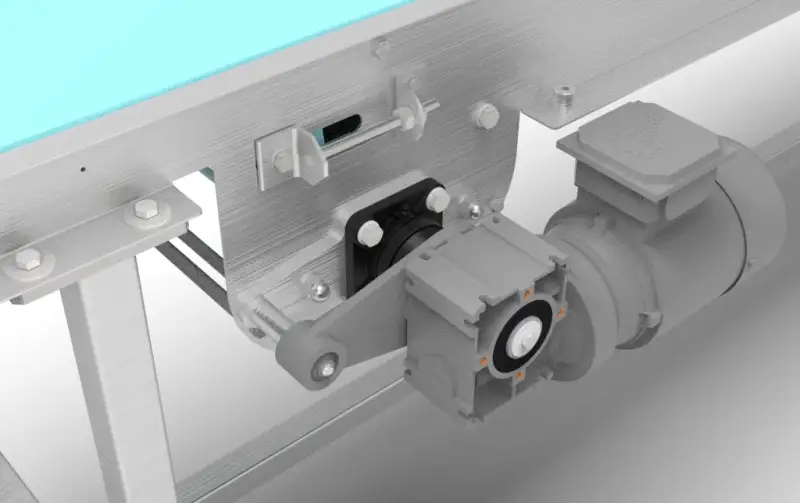

The hygienic design of this modular belt conveyor prioritizes the sanitation and hygiene standards of food manufacturing. The conveyor’s components are robust and durable, constructed with high-quality stainless steel materials, ensuring the conveyor’s ability to withstand the harshest cleaning agents and food residue. The modular belt conveyor features a flatbed with multiple rows of modular belts that are driven by a motor-driven sprocket, providing reliability and efficiency in the food production process.

Operation:

The modular belts on the flat bed of the conveyor create a continuous, smooth, and even flow of food products. The design features minimal crevices and gaps, reducing the risk of food residue accumulation and bacterial growth. The conveyor’s operation is straightforward, providing even distribution of food products within the production line.

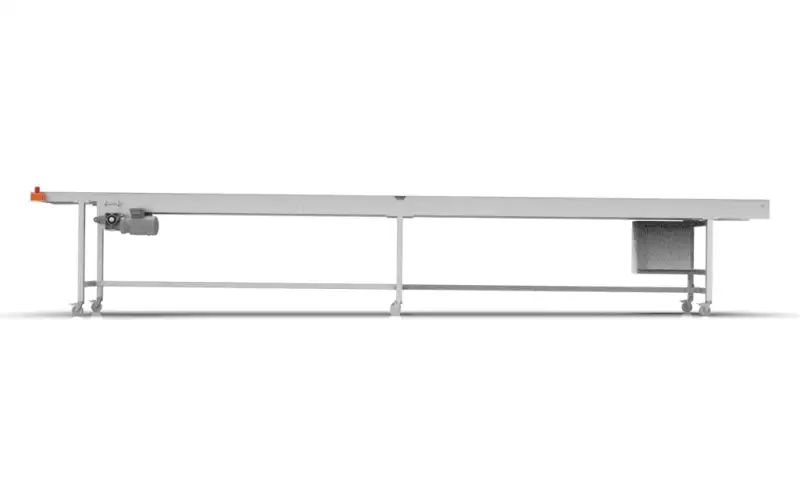

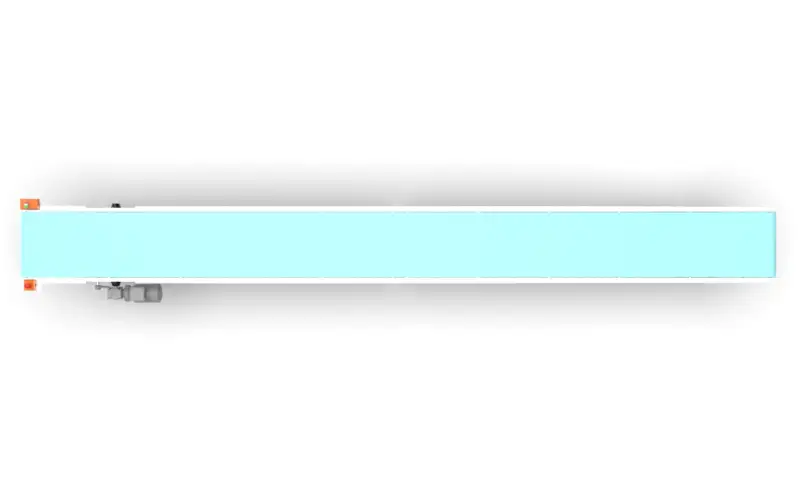

3D Design of a 5 m long, 450 mm wide modular belt conveyor for the food industry, the Solidworks design model of this modular belt conveyor for the food industry demonstrates a hygienic design that ensures safe and efficient transportation of food products. With its sturdy construction, reliability, and ease of operation, this conveyor is a vital component of any food manufacturing company that prioritizes food safety and quality.

This 3D model was designed by SolidWorks 2017, the file totaling is 56 MB, including step files for other 3D software open.