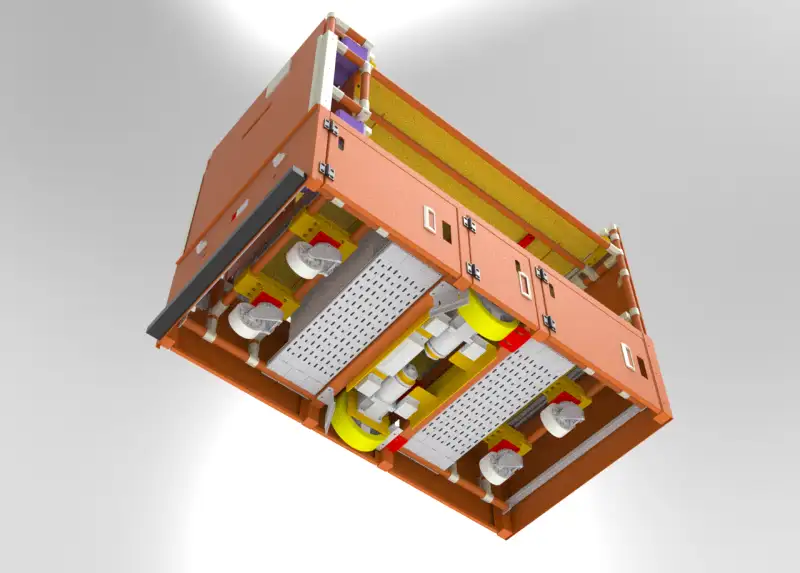

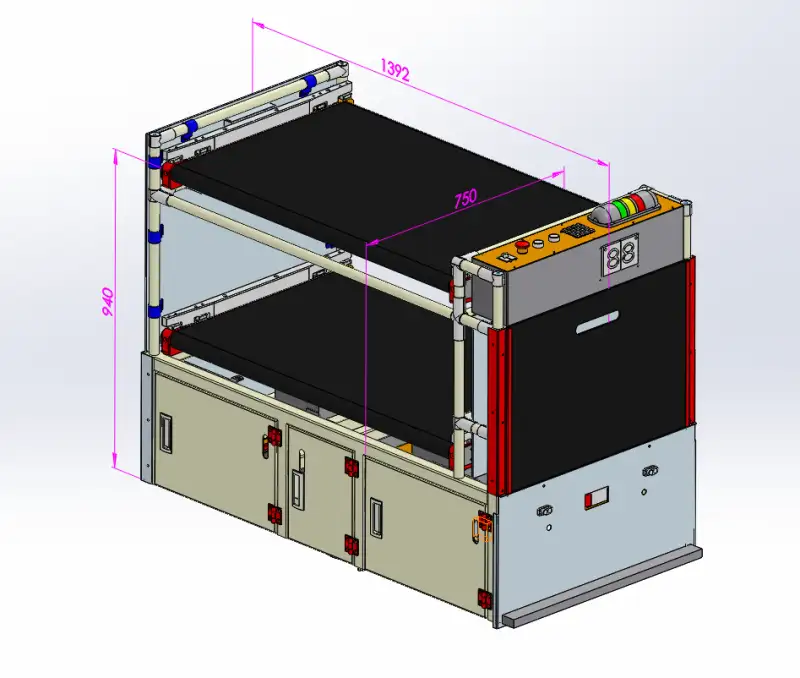

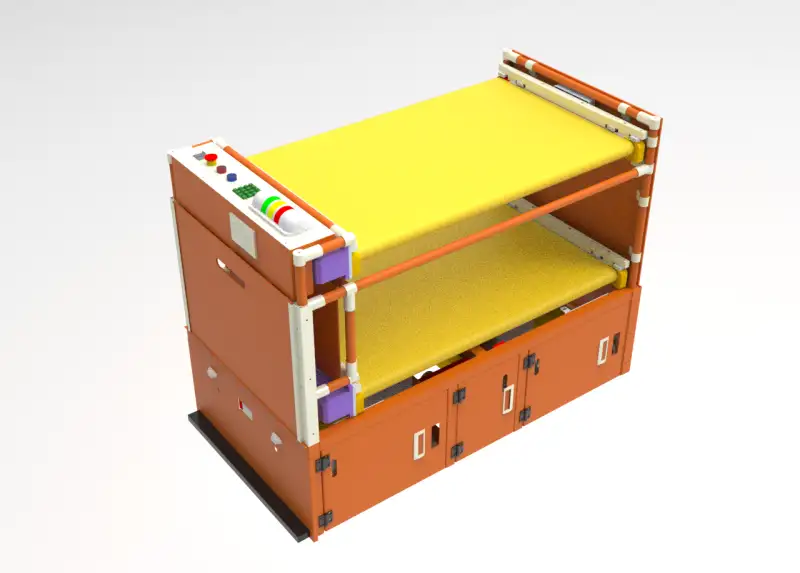

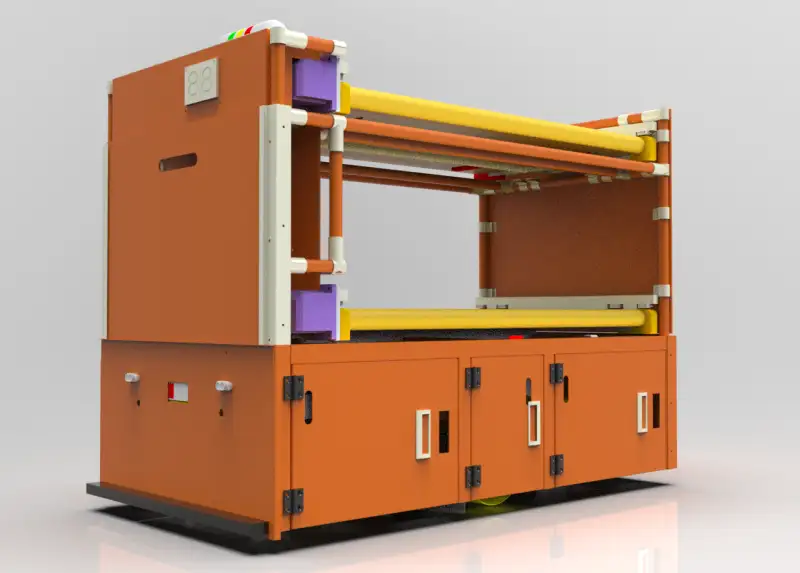

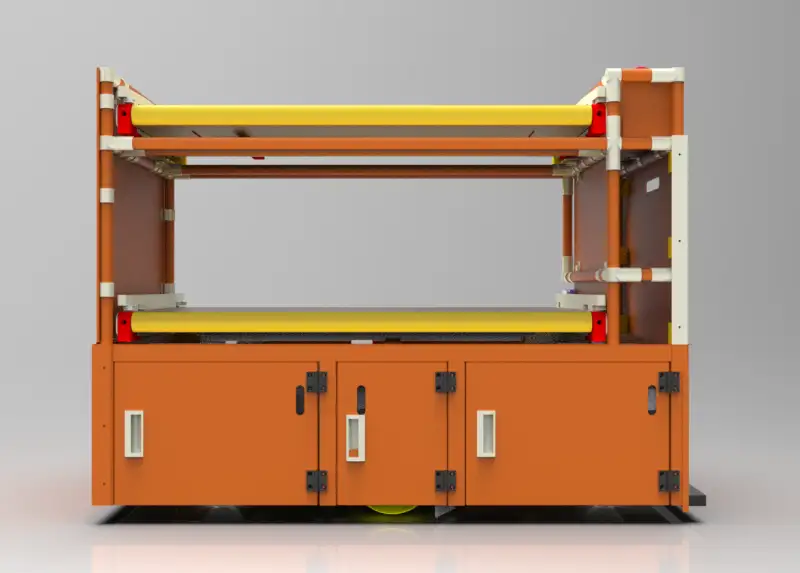

3D design model of the AGV carrier car A02

There are four main advantages of using AGV car automatic transportation tools: reduce the dependence on manpower, improve productivity, increase safety, and save floor space. The solution is mainly used for the automatic transportation of raw materials and accessories in the production process, docking of production lines, warehousing of finished products, etc.

AGV uses a robot system, which can operate normally without the intervention of the operator, thus greatly reducing the dependence on manual operation. Moreover, unless there is a failure, these automatic transportation vehicles can operate 24 hours a day, 365 days a year. Therefore, the production and warehousing processes will not be affected by shift change or worker attendance, and productivity will be greatly improved.

Those enterprises that rely on the development of transport systems will also greatly improve productivity once they upgrade to use AGV solutions, because these new products move faster and are different from constant-speed vehicles, and AGVs can accelerate as needed. Although the automatic transportation system has been very popular, many enterprises still use forklifts, which sometimes brings about safety risks, especially in the case of large warehouse traffic, accidents are more likely. In contrast, AGV mainly relies on sensors or moves on a fixed track, so the use of these automatic vehicle systems can greatly reduce the incidence of accidents.

The last advantage of AGV is its small range of movement and high accuracy. In the process of moving forklifts, more space is needed. In contrast, the solution of automatic transport tools rarely turns in the process of transporting goods. Therefore, enterprises can make full use of ground space to store more goods or expand the plant in the future.

The design is based on SolidWorks 2017, and the file total 17 MB.