Design concept and basic structure of box packaging machine

- design concept

The design concept of the box packaging machine is mainly based on efficiency, automation and flexibility. This machine is designed to reduce manual intervention and increase production efficiency, while being able to quickly adjust to different packaging needs. In addition, energy conservation and environmental protection are also important considerations in the design of modern box packaging machines.

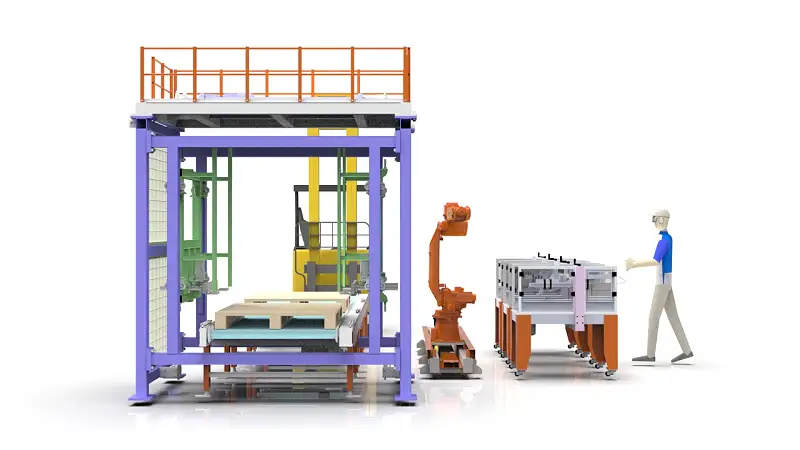

- Basic structure

Modern box packaging machines usually consist of the following main parts:

- Control system: including computer control system and sensors, responsible for monitoring the operating status of the machine and ensuring the smooth progress of the packaging process.

- Mechanical system: including various mechanical arms, conveyor belts and packaging mechanisms, responsible for completing various packaging actions.

- Electrical system: includes power supply, motor and various electronic components to provide power and control signals for the machine.

- Protection system: including safety protection devices and filtration systems to ensure the safety of operators and prevent dust pollution.

Work flow of box packaging machine

The workflow of a box packaging machine generally includes the following steps:

- The operator places the items to be packed into the feed port.

- The machine’s conveyor belt delivers items into the packaging area.

- The robotic arm places packaging materials (such as cartons, plastic bags, etc.) on the items to be packaged.

- Packaging materials are sealed by heat sealing, cold sealing or gluing.

- The packaged items are sent out from the machine outlet to complete the entire packaging process.

Application areas of box packaging machines

- Food industry: The food industry is one of the most widely used fields for box packaging machines. For example, it is used to package various snacks, drinks, meat and other products.

- Healthcare Industry: Equipment and products in the healthcare industry also require high-quality packaging. For example, medicines, medical equipment, etc. can be efficiently and accurately packaged through box packaging machines.

- Chemical industry: Products in the chemical industry often require protection measures such as moisture-proof and anti-corrosion. Box packaging machines can provide proper protection for chemical products through customized packaging materials and designs.

- Other industries: In addition to the industries mentioned above, box packaging machines are also used in many other fields such as retail, logistics, manufacturing, etc.

The future development trend of box packaging machines

- Intelligent: With the development of technologies such as the Internet of Things, big data and artificial intelligence, future box packaging machines will be more intelligent. This kind of intelligent machine will be able to better adapt to various packaging needs, perform fault diagnosis and repair independently, and even improve packaging efficiency and accuracy through machine learning and big data analysis.

- Personalization: With the diversification of consumer needs, future box packaging machines will be more personalized. This kind of personalized machine will be able to carry out customized design and production according to the characteristics and needs of different products to better meet the needs of consumers.

- Environmental protection: With the improvement of environmental awareness, future box packaging machines will be more environmentally friendly. This environmentally friendly machine will use more environmentally friendly materials and designs to reduce its impact on the environment. At the same time, more emphasis will be placed on energy efficiency and reducing energy consumption.

- Networking: Box packaging machines in the future will be more networked. This kind of networked machine will be able to be remotely monitored and maintained through the Internet, improving production efficiency and management efficiency. At the same time, it will also be able to be linked with other production equipment to realize the automation and intelligence of the production process.

- High precision and efficiency: Future box packaging machines will pay more attention to high precision and efficiency. This high-precision machine will better ensure the quality and consistency of each package and improve the added value and quality of the product. At the same time, this high-efficiency machine will be able to perform packaging operations faster, improving production efficiency and market competitiveness.

As an important industrial equipment, box packaging machines are widely used in all walks of life. With the continuous advancement of technology and changing social needs, future box packaging machines will develop in a direction that is more intelligent, personalized, environmentally friendly, networked, high-precision and efficient. These development trends will bring unlimited possibilities and opportunities for the future development of box packaging machines. At the same time, it will also have a profound impact on traditional manufacturing and promote the transformation and upgrading of the entire industry to digitalization, intelligence and greening.