Bearings, as crucial components in mechanical systems, play a vital role in ensuring the prolonged and efficient operation of machinery. Understanding and analyzing the life expectancy of bearings is essential for evaluating their performance and reliability. This article explores the concept of bearing life, the factors influencing it, and the methods used to calculate it.

1. Overview of Bearing Life

Bearing life refers to the duration a bearing can maintain normal operation under specific working conditions before reaching a certain fatigue limit. The fatigue limit is the load at which cracks begin to form in the bearing during continuous oscillation. The life of a bearing is often expressed through its rated life, representing the number of cycles at which 90% of a group of identical bearings can operate without failure under standard test conditions.

2. Factors Influencing Bearing Life

The lifespan of a bearing is influenced by various factors, and understanding these elements is crucial for a more accurate assessment of bearing life.

- Load: The load a bearing sustains is a primary factor determining its life. Excessive or uneven loads can lead to bearing fatigue, reducing its lifespan.

- Speed: High-speed operation increases friction and heat in bearings, significantly impacting their lifespan.

- Lubrication: Proper lubrication effectively reduces friction and wear, extending bearing life. Selecting suitable lubricants and regular replacement are critical for maintaining longevity.

- Temperature: High temperatures accelerate bearing wear, emphasizing the importance of maintaining suitable working temperatures.

- Environmental Conditions: Conditions such as dust, moisture, and other environmental factors can also affect bearing life.

3. Calculation Methods for Bearing Life

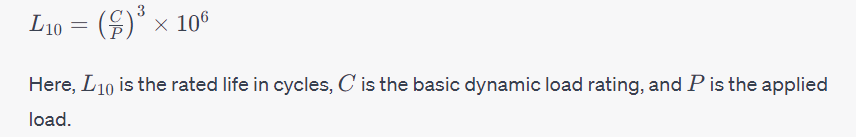

Bearing life is commonly calculated using the standard L10 life formula, where L10 represents the rated life in cycles.

This formula, based on statistical principles, denotes the number of cycles at which 90% of bearings under a given load can operate without failure.

4. Practical Case Analysis

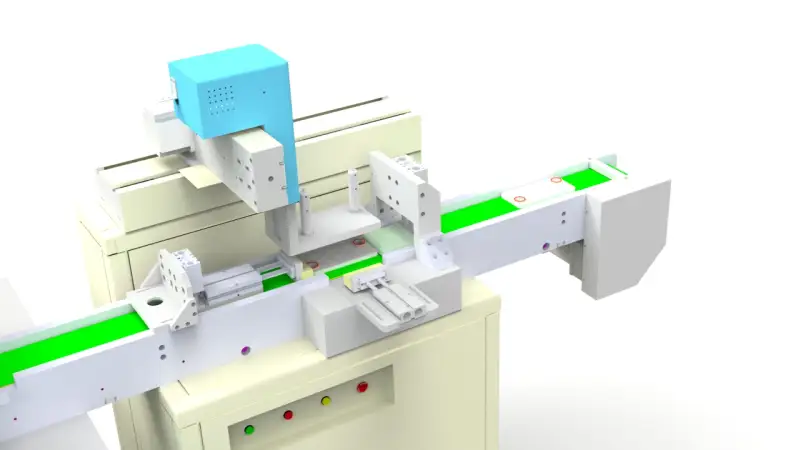

Practical case analyses provide a better understanding of the real-world application of bearing life calculations. For instance, consider the bearing in a conveyor; utilizing the formula based on its load and speed, the rated life can be computed. Regular monitoring of operational conditions allows for timely replacement of aging bearings, ensuring equipment reliability.

5. Conclusion

Bearing life is a critical metric for assessing the performance and reliability of bearings. Proper life calculations contribute to informed maintenance and replacement schedules. In practical applications, routine inspections of bearing conditions, coupled with appropriate lubrication and maintenance, are essential for extending bearing life and enhancing operational efficiency. A deeper understanding of bearing life calculations and influencing factors guides engineers in making informed decisions in equipment design and maintenance.