With the rapid development of the logistics industry, stacker cranes have been widely used in warehousing and logistics operations. However, in order to improve the efficiency and safety of stacker cranes, the intelligent application of sensors and perception systems has become crucial. This paper explores the application of sensors and perception systems in stacker cranes, analyzing their significant role in enhancing the autonomy and precision of these machines.

1. Introduction

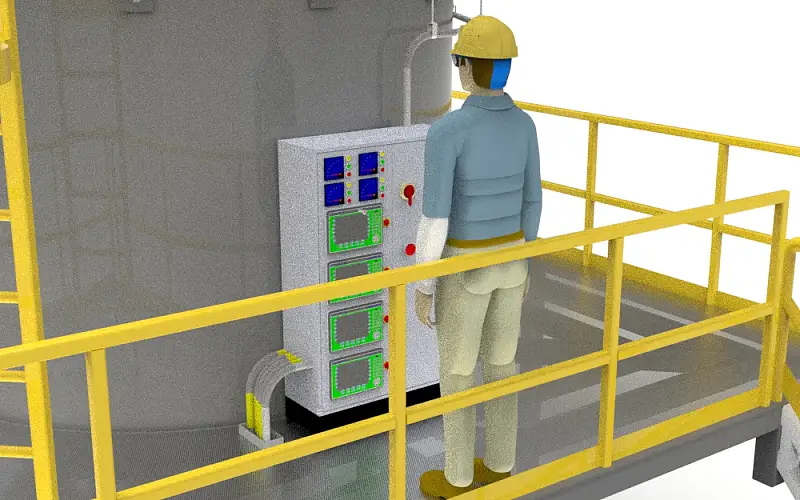

Stacker cranes are automated equipment widely used in the fields of warehousing and logistics, primarily designed to stack and transport goods from one location to another. Traditional stacker cranes relied on manual operation, but due to inefficiency and potential safety risks associated with human involvement, the introduction of sensors and perception systems has become essential.

2. Application of Sensors in Stacker Cranes

Sensors are the core components of perception systems, collecting and converting physical quantities in the environment into data that the control system requires. In the context of stacker cranes, sensor applications involve:

– Distance sensors: Used to measure the distance between the stacker crane and obstacles, ensuring that the machine avoids collisions during stacking operations.

– Weight sensors: Used to measure the weight of goods, allowing the stacker crane to control load stability during stacking and transportation.

– Tactile sensors: Used to detect the shape and surface characteristics of goods, ensuring that the stacker crane can correctly grasp and release items.

– Vision sensors: Utilizing image recognition and processing technologies, vision sensors detect and identify the position, shape, and features of goods, enhancing the precision of stacker crane operations.

3. Application of Perception Systems in Stacker Cranes

Perception systems integrate various sensors and algorithms to analyze and process sensor data, enabling the machine to perceive and understand its environment. In the context of stacker cranes, the application of perception systems mainly includes:

– Obstacle detection and avoidance: Perception systems monitor the surrounding environment of the stacker crane using distance sensors and vision sensors, automatically adjusting the machine’s path to avoid collisions and accidents.

– Goods recognition and classification: Perception systems, employing vision sensors and image recognition algorithms, classify and identify the goods that stacker cranes handle, ensuring accurate gripping and placement actions.

– Positioning and navigation: Perception systems, combined with sensors and positioning algorithms, achieve precise positioning and navigation of stacker cranes within the warehouse, improving the machine’s positioning accuracy and operational efficiency.

4. Advantages and Challenges of Intelligent Stacker Cranes

The application of sensors and perception systems provides intelligent stacker cranes with a range of advantages:

– Enhanced productivity: Automated stacker cranes can perform stacking and transportation operations accurately and rapidly, significantly improving warehousing and logistics efficiency.

– Increased safety: The introduction of perception systems enables stacker cranes to continuously monitor the environment, avoid obstacles, and effectively reduce the risk of accidents, enhancing workplace safety.

– Reduced labor costs: By reducing reliance on manual operation, stacker cranes with sensors and perception systems decrease labor costs and can operate continuously without the need for breaks, improving efficiency.

However, challenges exist in the utilization of sensors and perception systems:

– Sensor accuracy: different sensors may have inherent inaccuracies in various environments, requiring calibration and tuning to ensure precision and reliability.

– Data processing and analysis: sensor data collected needs to be processed and analyzed to extract valuable information, requiring suitable algorithms and software support.

– Technological updates and upgrades: To keep up with evolving technology, stacker cranes’ sensors and perception systems necessitate timely updates and upgrades to maintain performance and competitiveness.

5. Conclusion

The application of sensors and perception systems in stacker cranes greatly enhances their level of intelligence, enabling autonomous operations, precise stacking and transportation, and improved efficiency and safety. However, to overcome existing challenges, efforts should be made to enhance sensor accuracy, improve data processing, and analysis algorithms, and remain attentive to technological updates and upgrades. In the future, with the development of technologies such as artificial intelligence and machine learning, the application of sensors and perception systems in stacker cranes will continue to advance, offering more possibilities and opportunities for the logistics industry’s growth.