With the continuous advancement of industrial automation, stacker cranes play an increasingly vital role in the logistics industry. The automated control systems of stacker cranes significantly enhance the efficiency and safety of logistics warehousing processes, providing enterprises with a considerable competitive advantage. This article will explore the development history, key technologies, application prospects, and profound impact on the logistics industry and society as a whole.

**Part 1: The Development History of Automated Control for Stacker Cranes**

The automation of stacker crane control dates back to the early stages of industrial automation in the 1950s and 1960s. The earliest stacker cranes could only perform simple motion control through fixed programs and limited sensors. As computer technology advanced, the automated control of stacker cranes gradually achieved higher levels of autonomous decision-making. In the 1990s, automation control systems based on PLCs (Programmable Logic Controllers) and sensors became mainstream. However, these systems were limited by computing power and algorithm constraints, still possessing certain limitations.

Entering the 21st century, with the rapid development of information technology, cloud computing, and artificial intelligence, stacker crane automation control ushered in a new revolution. The introduction of machine vision, deep learning, and big data analysis technologies enabled stacker cranes to achieve more efficient and intelligent operations, including high-speed stacking, multi-task coordination, and autonomous recovery. These applications gradually lead stacker cranes towards full automation and intelligence.

**Part 2: Key Technologies of Automated Control for Stacker Cranes**

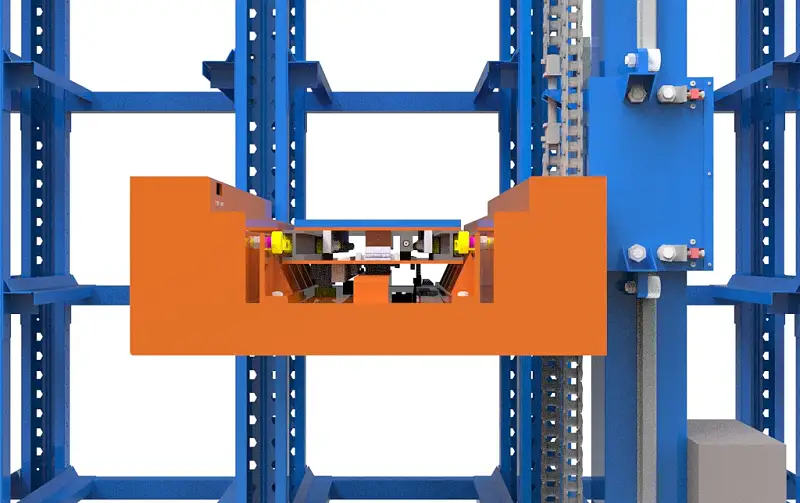

1. **Machine Vision Technology:** Machine vision systems are a core component of automated control for stacker cranes. Equipped with high-resolution cameras and image processing algorithms, stacker cranes can real-time perceive the surrounding environment and recognize the positions, shapes, and attributes of goods. This enables stacker cranes to perform more accurate gripping and placement, enhancing operational precision and efficiency.

2. **Deep Learning Algorithms:** Deep learning technology plays an increasingly important role in automated control for stacker cranes. By training neural networks, stacker cranes can learn and optimize motion planning, path planning, and obstacle avoidance strategies. This empowers stacker cranes to adapt to different scenarios and tasks, possessing more flexible and efficient decision-making capabilities.

3. **Sensor Technology:** Automated control for stacker cranes heavily relies on various sensors. Laser radar, ultrasonic sensors, infrared sensors, etc., can help stacker cranes real-time perceive obstacles and environmental information, enabling safe and efficient motion control.

4. **Communication Technology:** Stacker cranes often require real-time communication with logistics management systems or warehouse management systems. The adoption of efficient and reliable communication technology allows stacker cranes to coordinate with other devices, improving overall operation efficiency.

**Part 3: Application Prospects of Automated Control for Stacker Cranes**

Automated control for stacker cranes finds extensive applications in modern logistics industries, achieving significant achievements in various fields. The following are some application prospects of automated control for stacker cranes:

1. **Efficient Logistics Warehousing:** Automated control for stacker cranes can achieve high levels of automation in logistics warehousing systems, improving the turnover rate and operational efficiency of warehouses. Unmanned operations can also continue 24/7, maximizing time and labor resource savings.

2. **Intelligent Logistics Parks:** Combining automated control for stacker cranes with the intelligence of logistics parks can achieve automated sorting, loading, and dispatching of goods, optimizing logistics paths and transportation plans, reducing logistics costs, and enhancing the transparency and responsiveness of logistics supply chains.

3. **Operations in Hazardous Environments:** In hazardous environments,

such as high temperatures, low temperatures, toxic gases, etc., automated control for stacker cranes can avoid direct human involvement, reducing safety risks and protecting the safety of employees.

4. **Space-Limited Scenarios:** In space-limited scenarios, automated control for stacker cranes can achieve efficient space utilization and cargo storage, increasing warehouse storage density and throughput.

Automated control for stacker cranes is an essential part of the development of industrial automation. With the continuous progress of machine vision, deep learning, sensor technology, and communication technology, stacker cranes’ automated control will become more intelligent, efficient, and safe. It not only improves efficiency and reduces costs in the logistics industry but also has broader applications in other fields, bringing more convenience and benefits to people. However, as automated control technology continues to advance, equal attention should be given to issues such as safety and data privacy to ensure the reliability and stability of automated systems. Only through continuous innovation and improvement can automated control for stacker cranes continue to drive the development of the logistics industry towards a more intelligent future.