In today’s fast-paced industrial landscape, automation has become the norm. The manufacturing industry constantly seeks to streamline its processes to reduce production costs, increase output, and improve efficiency. The labeling process is an essential part of most manufacturing plants, requiring workers to spend significant time and resources labeling products manually. However, with the advent of automatic labeling machines, manufacturers can automate their labeling process and achieve significant savings in time and cost. This article explores the features and benefits of automatic labeling machines and how they have revolutionized the manufacturing industry.

What is an Automatic Labeling Machine?

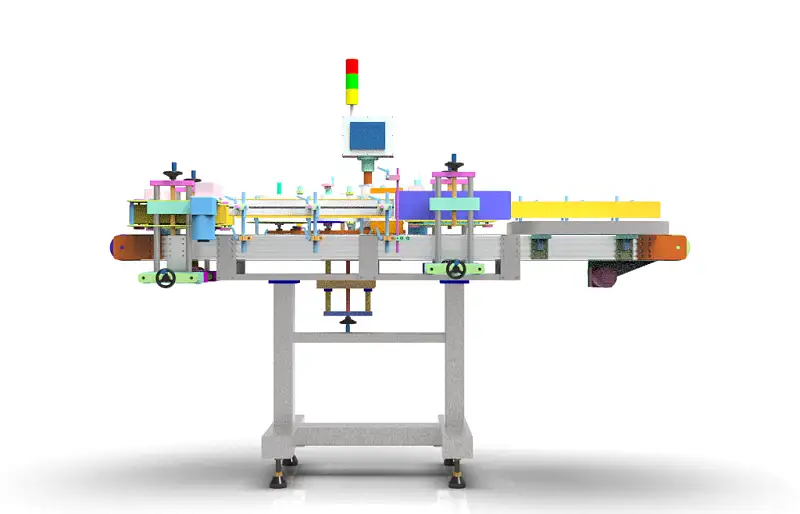

An automatic labeling machine is a device that automatically applies labels to products. The machine can be fully or semi-automated and can label various types of products, from bottles and jars to boxes and bags. Automatic labeling machines use different label application methods, including pressure-sensitive labeling, hot melt labeling, and cold glue labeling. Additionally, they offer different label handling and application capabilities, such as wrap-around, front and back, and 360-degree labeling.

Features of Automatic Labeling Machines

Automatic labeling machines are equipped with various features that make them versatile and user-friendly. First, they can handle various label sizes and shapes, enabling manufacturers to label products of different shapes and sizes with ease. Second, they come with high-speed labeling capabilities, making them capable of labeling hundreds to thousands of products per hour. Third, they come with advanced sensors and controls that ensure accurate label positioning and application. Fourth, they can be easily integrated into existing production lines, allowing for seamless integration and operation.

Benefits of Automatic Labeling Machines

There are several benefits of using automatic labeling machines in manufacturing environments. First, they enhance production efficiency, increasing production rates and reducing production costs. Second, they improve product quality by ensuring that labels are accurately applied, reducing the risk of errors and inconsistencies. Third, they ensure compliance with regulatory standards, particularly in the food and pharmaceutical industries, where accurate labeling is crucial. Fourth, they improve workplace safety by reducing the risk of injuries associated with manual labeling processes. Fifth, they increase worker productivity, freeing up resources to focus on more complex tasks.

Impact of Automatic Labeling Machines on the Manufacturing Industry

The introduction of automatic labeling machines has had a significant impact on the manufacturing industry. Manufacturers can now automate their labeling process, reducing costs, improving efficiency, and ensuring compliance with regulatory standards. Automatic labeling machines have also freed up workers’ time, allowing them to focus on more complex tasks that require critical thinking and problem-solving skills. Additionally, they have made labeling processes safer by reducing the risk of injuries associated with manual labeling. Overall, the adoption of automatic labeling machines has revolutionized labeling processes, enabling manufacturers to produce high-quality products at a lower cost.

The introduction of automatic labeling machines has transformed the manufacturing industry by enabling manufacturers to automate their labeling process, increasing production rates, reducing production costs, and improving efficiency. Automatic labeling machines come with different label handling and application capabilities, making them versatile and user-friendly. They also offer several benefits, such as improving product quality, ensuring compliance with regulatory standards, and improving workplace safety. As such, they have become a crucial component of modern manufacturing plants and are likely to continue driving efficiency and productivity gains in the industry.