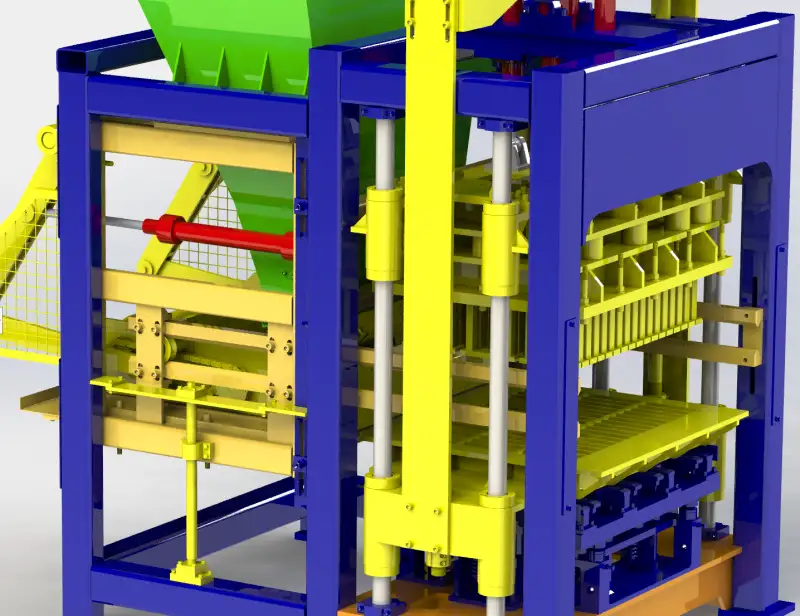

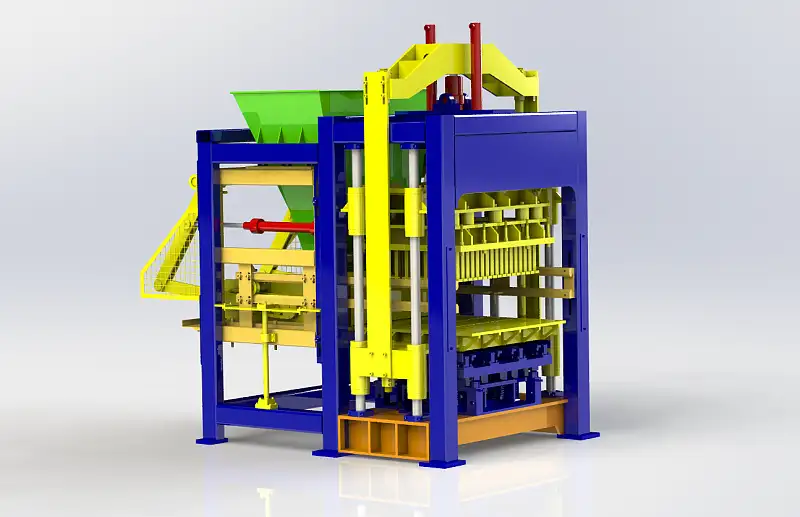

3D model drawing of full automatic brick making machinery and industrial equipment

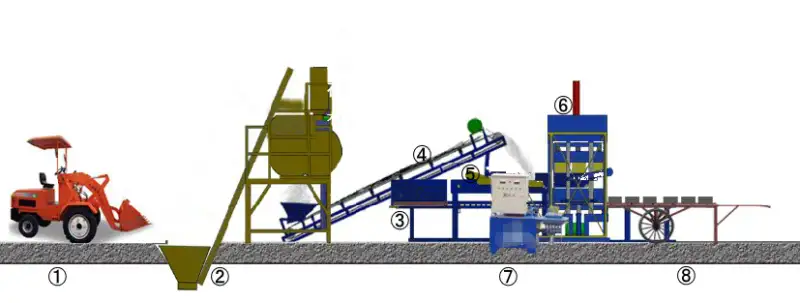

Construction waste brick making process:

Construction waste crushing – Transportation (steel, metal material suction) – batching – mixing – brick molding – palletizing – maintenance

Tailing brick making process:

1. Tailings, cement, other raw materials, batching – Transportation – mixing – brick molding – palletizing – curing

2. Tailing as the main raw material for autoclaved standard brick, please refer to: autoclaved standard brick production line equipment

3. Tailing as the main raw material for autoclaved aerated concrete block, please refer to: aerated concrete block production equipment should be combined with the main components and content of tailing to select different tailing brick making process

Fly ash brick making process:

1. The unburned cement brick is a brick product that can be put into use by using 1-2 kinds of fly ash, slag, coal gangue, slag, sand, stone powder and construction waste, mixing a small amount of cement (combined with the actual situation), forming and natural maintenance.

2. Fly ash brick is made of silica raw materials (fly ash, slag, sand, etc.) and lime and water under high pressure. It is a modern wall material with good performance and economic applicability. On the market, it is called lime sand brick, fly ash brick and so on. According to different raw materials, it is called differently. Equipment of steam curing and autoclaved standard brick production line

3. Fly ash aerated concrete brick is a kind of porous, light, heat preservation and heat insulation concrete material which is made by adding fly ash, lime, gypsum, water and aerator into cement slurry and curing by mechanical mixing. Its structure and performance are similar to autoclaved aerated concrete, but it has the characteristics of simple production process and convenient construction.

| Forming design speed | 15-20s per mold | Product specification |

| Vibration frequency | 1000-4200 times/min (adjustable) | 240×115×53mm (48 standard bricks per mold) |

| Exciting force | 20-50N (adjustable) | 390×190×190mm (10 bricks per mold) |

| Total power | 41 (KW) | 240×115×90mm (24 perforated bricks per mold) |

| Theoretical daily output | 115200 pieces (standard bricks) | 250×250×60mm (6 pavement bricks per mold) |

| Pallet size | 1080×860×35-40mm bamboo | 225×111×60mm (24 pavement bricks per mold) |

| Machine quality | 14.6T | 200×100×60mm (24 pavement bricks per mold) |

| Dimensions | 3500×2100×2600mm |

The design based on SolidWorks 2017, please use 2017 or above to open. The file is about 63.5 MB.